RESEARCH Overview

We are a team of interdisciplinary scientists and engineers who create new electronic and other functional materials the “natural way”. We look to Nature for inspiration and guidance in materials design at the molecular, supramolecular, and manufacturing levels. In doing so, organic metal and semiconductors can be constructed to possess properties typically not associated with these materials, such as adaptability, transformability, self-healing capability, and biodegradability. We also keep environmental sustainability in mind by practicing green chemistry for synthesis and additive manufacturing for processing. Furthermore, we are working towards directly using biological organisms to carry out the design for synthetic materials. The unique combination of properties from these bioinspired, biological, and bio-designed functional materials can unravel new, transformative technological advances in healthcare, sustainability, defense, and energy.

Our main research areas are described in the sections below.

Our work is funded by:

Dynamically Adaptive Polymers

—The stronger the impact, the stronger the material

Our society is facing a challenging plastics (i.e., polymers) and electronics waste dilemma. There has been an ongoing, multifaceted effort to find solutions to this problem. One of the sources of waste comes from the premature aging of, or damage to, materials. When plastics and electronics are accidentally dropped or hit, the energy associated with high-rate impact can damage them. If these items are relatively low cost, as many plastic items are, we toss them away long before the end of their expected lifetime, creating unnecessary waste. We have accepted that more rapid or stronger impact equals higher probability of damage. In contrast, biological organisms often behave the opposite—they adapt. For example, the muscles that are most frequently used grow stronger rather than weaker, and bones can change shape over time to better accommodate our unique posture. Such divergence propelled us to ask: “What if we could figure out a way to make synthetic materials adaptive to impact rates, so that they would be less prone to accidental damage?” In other words, we want materials to behave counterintuitively— they should become stronger upon greater impact. This vision has led to the first research area of our group.

Representative publications:

“Deformation-Rate Adaptive Conducting Polymers and Composites” [Link]

“Oligoaniline-Assisted Self-Assembly of Polyaniline Crystals” [Link]

Functional Architected Materials Through 3D Printing

—Lightweight but strong, complex yet high throughput

The previous research direction explored chemical strategies to tune mechanical properties. If we examine Nature, many resilient materials are cellular (i.e., porous). For example, the different shapes of tree cells make different parts of the tree more resilient to compressive and tensile stresses, endowing the trunk with better load-bearing properties and the branches with more flexibility to deform under strong wind. Based on this idea, we envisioned a different route to tune the mechanical properties of materials, particularly those of organic electronic materials, by tuning their microscopic architecture rather than by chemical design. Such a feat by traditional means would be very challenging, but it is now feasible using emerging 3D printing technologies. This was how the second research direction in our lab, 3D printing of organic electronic materials, was conceived.

Representative publications:

“3D Printed Architected Conducting Polymer Hydrogels” [Link]

“Imparting High Conductivity to 3D Printed PEDOT:PSS” [Link]

“3D Printing of Conjugated Polymers” [Link]

“A New and Versatile Template Towards Vertically Oriented Nanopillars and Nanotubes” [Link]

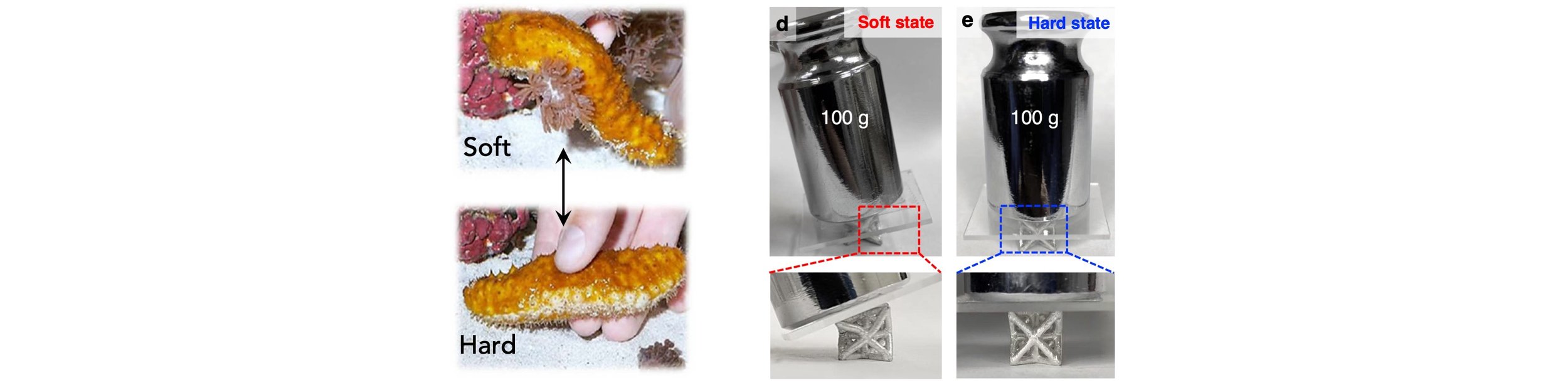

Transformative Materials

—Switchable between soft and hard

In the world of synthetic materials, hard and soft materials are considered different categories of materials, each with their distinct field of applications. In contrast, some biological organisms have evolved to possess both soft and hard states, with the ability to transition between the two states on cue. For example, sea cucumbers are typically soft and can deform considerably to squeeze through thin channels. However, when threatened by predators, they can transition into a hard and stiff entity for self-protection. We wondered, how exciting would it be if we could create electronic materials that can behave like a sea cucumber? These materials could be hard under normal usage, but with a click of a button, transition to a soft state that allows the device to be rolled or folded up to store in our pockets, or to be deformed to fit irregularly shaped, tight spaces for transportation. This curiosity has led to the third research direction in our lab.

Representative publications: In progress

Bio-design

—Harnessing biological intelligence for synthetic materials

We have been inspired by the many design principles from Nature that have led to the formation of the previous research directions in our lab. The next question, naturally, is can we directly employ Nature to work for us? Can Nature design synthetic materials with unexpected, enhanced, and/or adaptive properties just like biological materials? Along this concept of bio-design, we started exploring an organism, slime mold, that has been shown to create intelligent network designs on a short timescale in the absence of a brain. They have been “tricked” to solve mazes and design transportation networks in research by other groups through strategically placed food sources. We are currently exploring “tricking” slime mold to design adaptive load bearing structures and smart circuits. This work may shed insights on potential pathways to enhance material sustainability by employing Nature.

Representative publications: In progress